Cable Climbing System + Tower Climber = FREE CLIMBING / NOT ALLOWED if you follow OSHA regulations.

I mentioned earlier this week that I wanted to start a conversation. Some of the topics I’ll be hitting on will be unpopular, but hey…that’s why I’m here. If we don’t bring things out into the open, how will people know there’s an issue and how do we find a solution? So, let’s get started.

An Observation

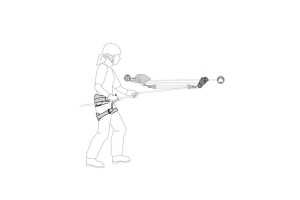

While observing a tower climb last week, I noticed the climber was not two points connected (fall restraint/fall arrest) while on their cable life line. Hmm. According to OSHA/ANSI standards and regulations (references below), without a secondary or an OSHA approved ladder system or rated anchorage step pegs, this is considered “free climbing” and unfortunately, an accepted practice in the wireless industry.

I asked the climber if he considered it free climbing. I also asked what if his fall restraint failed or the cable climb was not installed correctly. Finally, I asked where his secondary was. The climber had no answer to any of my questions.

I guess we’re to assume if the first climber makes it to their work area safely, then we got lucky and it’s a “good to go” for the rest of the team? We can’t assume hands and feet are our fall protection when our single point of attachment is a cable grab with unrated step bolts and no ladder system in place.

Climbers are continuously at risk with these “safety climbs.” For instance, what if the step bolts break off due to defective welding or the system is installed incorrectly? Is this compliant with OSHA/ANSI standards without a secondary? Let’s see.

The Standards

ANSI A14.3

7.1.4 The ladder safety device shall be designed to absorb the impact of a solid object weighing at least 500 pounds in a free fall of 18 inches.

7.1.3 Design and installation of mountings shall not reduce the design safety factors of the fixed ladders.

7.3.1The safety sleeve shall be of a type which can be operated entirely by the person using the ladder safety device. It shall permit the person using the ladder safety device to ascend or descend without having to continually manipulate the safety sleeve.

7.3.3 The maximum length of the connection between the centerline of the carrier and the point of attachment to the body belt shall not exceed 9 inches.

These standards assume that both feet would be required to climb, and a climber will use one hand for the rung to maintain three points of contact while climbing a ladder.

OSHA 1910 General Industry, Subpart D, 1910-23 Ladders

1910.23(b)(12) Each employee uses at least one hand to grasp the ladder when climbing up and down

OSHA 1917 Maritime Terminals, Subpart F, 1917-118 Fixed Ladders

1917.118(b)(3)"Ladder safety device" means a support system limiting an employee's drop or fall from the ladder, and which may incorporate friction brakes, lifelines and lanyards, or sliding attachments.

1917.118(e)(1) Fixed ladders more than 20 feet (6.1 m) in height shall be provided with a cage, well, or ladder safety device.

1917.118(e)(3) Ladders equipped with ladder safety devices shall have rest platforms;

1917.118(e)(4) Where used, ladder safety devices shall:

1917.118(e)(4)(i) Be installed and maintained in accordance with the manufacturer's instructions, which shall be available for

1917.118(e)(6) Ladders installed after (effective date of standard) on radio, microwave communications, electrical power and similar towers, poles and structures, including stacks and chimneys, shall meet the requirements of this paragraph (e).

1917.118(f) Individual rung ladders. Ladders consisting of individual rungs that are attached to walls, conical manhole sections or river cells shall:

1917.118(f)(1) Be capable of supporting a load of 350 pounds (1557 N) without deformation;

1917.118(f)(2) Form a continuous ladder, uniformly spaced vertically from 12 inches to 16 inches (30.5 to 40.6 cm) apart, with a minimum width of 10 inches (25.4 cm) and projecting at least 4½ inches (11.43 cm) from the wall;

1917.118(f)(3) Be so constructed that an employee's foot cannot slide off the ends; and

1917.118(f)(4) Be firmly attached and without sharp edges.

OSHA 1926 Construction, Subpart X, 1926-1053 Ladders

1926.1053(a) (23) The mounting of ladder safety devices for fixed ladders shall conform to the following:

1926.1053(a)(23) (i) Mountings for rigid carriers shall be attached at each end of the carrier, with intermediate mountings, as necessary, spaced along the entire length of the carrier, to provide the strength necessary to stop employees' falls.

1926.1053(a)(23)(ii) Mountings for flexible carriers shall be attached at each end of the carrier. When the system is exposed to wind, cable guides for flexible carriers shall be installed at a minimum spacing of 25 feet (7.6 m) and maximum spacing of 40 feet (12.2 m) along the entire length of the carrier, to prevent wind damage to the system.

1926.1053(a)(23)(iii) The design and installation of mountings and cable guides shall not reduce the design strength of the ladder.

1926.1053(a)(24) The side rails of through or side-step fixed ladders shall extend 42 inches (1.1 m) above the top of the access level or landing platform served by the ladder. For a parapet ladder, the access level shall be the roof if the parapet is cut to permit passage through the parapet; if the parapet is continuous, the access level shall be the top of the parapet.

I’ll just leave that right there and give it a little time to be digested and maybe stir up some questions or comments.

Next week in Part II, let’s talk about who’s responsible for towers without OSHA/ANSI approved ladder or cable systems. Sounds like fun, right?

Until next time….

SS, aka the Desert Piranha